Author: David Richards | Published on: 19/03/25

Introduction

PCB prototyping is a critical step before mass production. It helps identify design flaws, test circuit functionality, and optimize layouts. However, many beginners and even experienced designers make avoidable mistakes that lead to costly revisions. In this guide, we’ll explore common PCB prototyping errors and how to prevent them.

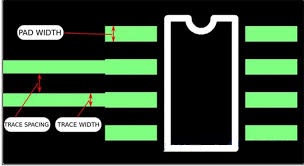

1. Incorrect Trace Widths and Spacing

✅ Why It Matters:

Traces that are too thin can overheat, while traces that are too close can cause short circuits.

🔹 Solution:

- Use an online trace width calculator to determine the correct size based on current requirements.

- Follow the manufacturer’s minimum clearance guidelines (e.g., JLCPCB, PCBWay).

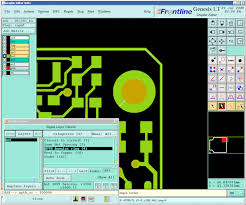

2. Ignoring Design Rule Checks (DRC) & Electrical Rule Checks (ERC)

✅ Why It Matters:

Skipping DRC/ERC in PCB design software can lead to overlapping traces, insufficient clearances, and electrical errors.

🔹 Solution:

- Always run DRC/ERC checks before exporting Gerber files.

- Configure Eagle, KiCad, or Altium with your manufacturer’s specs.

3. Poor Component Placement

✅ Why It Matters:

Bad component placement can cause signal integrity issues, inefficient routing, and difficulty in soldering.

🔹 Solution:

- Place high-speed signal components as close as possible to minimize interference.

- Avoid placing components too close to board edges (especially connectors).

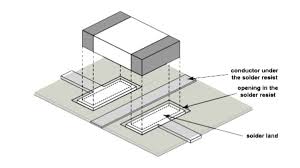

4. Forgetting Thermal Relief for Soldering

✅ Why It Matters:

Without proper thermal relief, soldering large copper areas becomes difficult, leading to cold joints.

🔹 Solution:

- Use thermal relief pads around vias and large copper pours.

- Enable the thermal relief option in your PCB design software.

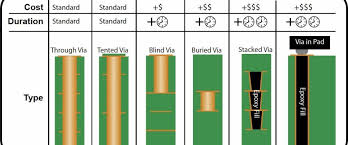

5. Wrong Via Sizes and Annular Rings

✅ Why It Matters:

Incorrect via sizes can make it impossible to manufacture your PCB or result in weak connections.

🔹 Solution:

- Check the minimum via sizes required by your PCB manufacturer.

- Use tenting vias for a cleaner design and prevent solder paste from filling holes.

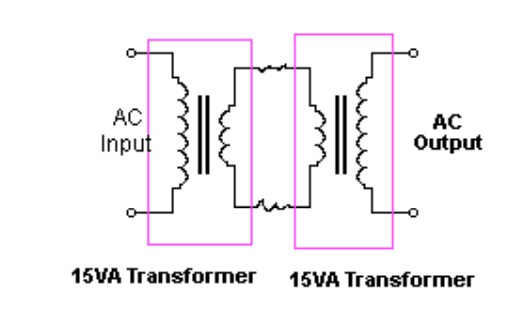

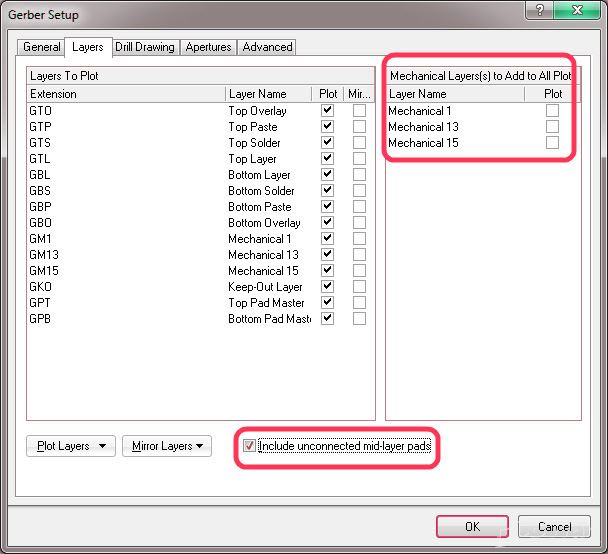

6. Not Generating Gerber Files Correctly

✅ Why It Matters:

Incorrectly generated Gerber files can lead to missing layers, incorrect drill holes, and failed fabrication.

🔹 Solution:

- Before sending to a manufacturer, view Gerber files using a Gerber Viewer.

- Ensure you include all necessary layers (Top, Bottom, Silkscreen, Drill Files).

Conclusion

PCB prototyping is an essential part of the electronics development process. By following these best practices, you can reduce errors, save time, and avoid costly revisions before sending your design for manufacturing.

🔹 Next Steps:

✅ Double-check your design with DRC/ERC

✅ Use correct trace widths & via sizes

✅ Review your Gerber files before submission

If you found this guide helpful, share your PCB prototyping experiences in the comments! 🚀